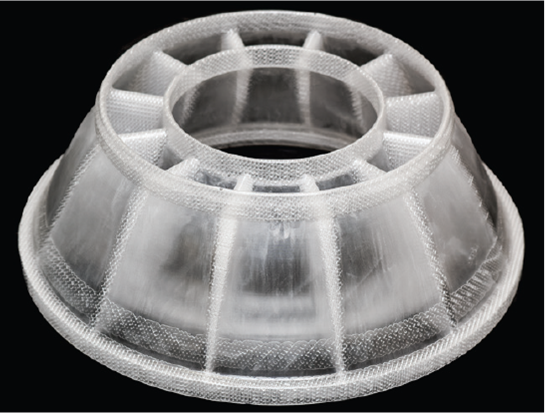

Technology : Neo800 3D printer

Application: Investment Casting Pattern

Build Time: 44 hours 42 mins

This master pattern was printed on the Stratasys Neo800 3D printer with Somos® WaterShed AF. Utilising Materialise TetraShell software, large master patterns can be produced on the Neo800 with intricate designs and smooth sidewall quality, which reduces or in some instances eliminates any part finishing time. Printing short-run master patterns with the Neo stereolithography results in significant cost and lead time savings compared to traditional methods. Somos® WaterShed AF meets the needs for 3D printing investment casting patterns. As no antimony is used, patterns created with Somos® WaterShed AF leave only 0.05% of ash residue after burnout, reducing clean-up and speeding up mold production.

Investment casting projects done additively deliver substantial cost saving by eliminating two steps of the traditional process. Three to four such projects justify an investment in a Neo800 3D Printer!

To learn more about this lucrative use case, please refer to this presentation.

|